STANDARDS

Motors are designed according to Standards and to relevant Standards. On request, motors can also be constructed and tested according to other standards.

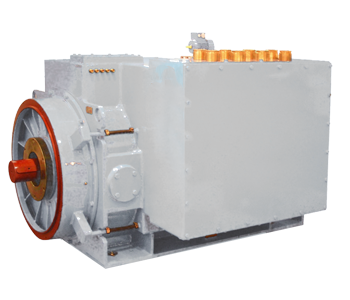

Motor design

Stator Casing

The ribbed frame and end shields are made of cast iron or of welded steel plates. Shape and dimensions are selected to ensure minimum vibrations and are designed to ensure easy transport and installation.

Stator Core with Winding

The stator core is made of silicon steel sheet having low magnetic losses. Upon stacking and fixation of lamination on the appropriate device, the complete winding is inserted, fixed and connected. Afterwards, the core with winding is subjected to the manufacturing process of vacuum pressure impregnation to complete the insulating process. Upon the completion of the procedure, stator is inserted in the stator frame.

Stator Winding and Insulation

Stator windings are constructed from copper rectangular wires. The wires are preinsulated with enamel varnish in combination with glass silk and varnish. The winding is of double layer type, made of individually shaped and continuously insulated coils. The basic materials are mica and epoxy resins.

Prepared coils are continuously taped along the whole length with porous tapes on the basis of glass and mica paper. Such insulated and tested coils are inserted in the stator core, and then all the required connections and tests are carried out prior to vacuum pressure impregnation. The process of vacuum pressure impregnation is followed by the stiffening process in furnace, tests and the insertion of the stator core with winding into the frame.

Then the final tests are performed. The insulation system is of class. It is moisture proof and it practically has no limitation with regard to climate conditions, salty atmosphere, acids and lies. By the mentioned insulation system, great mechanical strength of the winding ends has been obtained. There is no limitation to reversals at residual fields of any magnitude and phase angle.

Rotor Assembly

Grease lubricated rolling bearings or oil lubricated slide bearings as appropriate to speed and bearing loading are used. On horizontal motors of all sizes, oil lubricated slide bearings are an option. Bearings are installed in bearing endshields. Rolling bearings are provided with grease nipple, grease drain box and grease regulator. Regreasing is possible during motor running. Vertical motor thrust bearing is placed on the top of the motor.

Slide bearings are equipped with bearing shells spherical seated in the housing. Bearings are fitted with loose lubricating rings. Depending on speed of rotation and on bearings specific load, bearings are available either with natural cooling or with connections to a lubricating system.

The bearing oil-ring maintains lubrication when force-feed oil supply fails, allowing the motor to come safely to a standstill. Normally, slide bearings are non-locating bearings. To prevent oil vapor ingress into the motor enclosure, the inner side of bearing endshield is provided with additional motor seal.

Main Terminal Box

Main terminal box is constructed according to REQUEST. It can be supplied with one, two or three cable glands for cable inlet with maximum OD of 76 mm. The terminal box is situated on top and cable entry can be at the right-hand side or at left-hand side.Terminal boxes are supplied with earthing terminals.

Direction of Rotation

Motors of all sizes are made for one direction of rotation, but on request, motors for both directions of rotations are available.

Additional Equipment

On request, conforming to drive requirements additional equipment can be installed on, such as:

- additional resistance thermometers in windings

- resistance and/or contact thermometers in bearings

- equipment for vibration monitoring

- equipment for speed measurement